- Top>

- Products, Production, Purchasing>

- Production System / Manufacturing

Production System / Manufacturing

Introducing Our Manufacturing

We aim for low cost, high quality manufacturing by using simple, automated equipment that incorporates the ideas of TPS (Toyota Production System).

We aim for low cost, high quality manufacturing by using simple, automated equipment that incorporates the ideas of TPS (Toyota Production System).

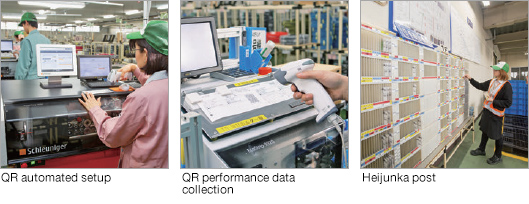

Production systems

With a view to achieving the three principles of high quality, short delivery time frames, and low cost, the various departments of our company work together to implement constant improvements, based on the Toyota production system. In addition, through the use of automated conveyance, robots, karakuri*, and more, G.S. Electech achieve simple, streamlined, compact, and low-cost automation. Our goal is to carry out sophisticated monozukuri manufacturing and human resource development that continues to earn the trust of our customers.

*"Karakuri" refers to the use of natural energetic forces such as gravity to create simple systems.

Examples of Simple, Automated Equipment

Automated transportation systems

With Automated Guided Vehicles (AGV), magnetic tape or magnetic circuits are placed on the floor. The electromagnetic energy generated guides conveyance carts along a track without the help of humans.

On our company's production lines, the AGV system allows for accurate supply of materials within the specified time frame and in accordance with specified commodities, as well as for pickup of finished products. This serves to shorten lead time and cut logistics costs and inventory.

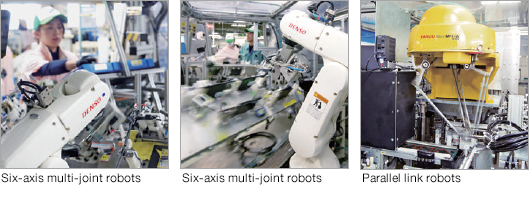

Robot-performed processing

In view of near-future technical innovation in robotics, G.S. Electech began actively utilizing robots as of 2005. In the field of harness processing--harnesses being flexible items--automation was once thought to be an insurmountable task, but our company has managed to develop automated facilities utilizing work robots positioned to assemble, process, and set products.

At present, we have 150-plus robots working on our assembly lines--a place where people and robots successfully coexist!

G.S. Electech Kyushu, Inc. Machinery & Tools Center

The Machinery & Tools Center designs and produces dedicated equipment for our Group manufacturing locations. Using 3DCAD and other equipment, we carry out everything from design to parts processing to assembly in an integrated way, yielding superior quality, lower facility costs, and shortened lead time.

A focal point for developing new processing technologies, the Center has been an incubator for innovative ideas that have contributed to the realization of automated assembly processing previously believed impossible.